Motion Control – Application – Underwater Inspection

Motion Control – Application – Inspecting flooded pipes of power plants requires skilled, high-precision handling. And the robotic vehicles have to be optimized accordingly, for example to dive 20 m deep. The new seawater manipulator is capable of maneuvering underwater in pipes, where it can be used to perform inspections. RE motors by maxon are responsible for the dynamic drive of the robot.

Taunton, MA — Motion Control Application – In robotics, manipulators are those devices that enable physical interaction with their surroundings. For this interaction, the robotic vehicles are equipped with appropriate tools, gripper systems or measuring devices. In the case of the seawater manipulator, this equipment largely consists of high-performance cameras used for pipe inspection. Ibass, from Augsburg in Germany, develops, manufactures and distributes manipulators for various in-pipe applications: inspection, grinding, welding, retrieval or suction.

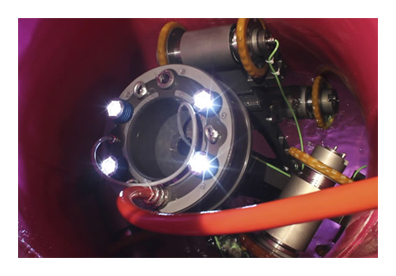

The manipulators consist of a driving unit, the required work module and a camera. They are operated electrically and pneumatically and therefore drag along lines behind them. The target groups for these small robotic vehicles are primarily operators of power plants and refineries, as well as pipe manufacturers and assembly fitters of pipeline systems: “For example, we make perfectly executed welding seams during assembly possible,” explains Michael Strasser, managing director of Ibass.

The area of application of the seawater manipulator includes visual inspection of power plant coolant pipes that cannot be emptied (a task that requires a manipulator suitable for seawater use). Furthermore this type of manipulator is also used for applying inner coatings to pipelines, as sealed wheel units are absolutely mandatory for this application. The seawater manipulator developed by Ibass can maneuver and inspect pipes with inner diameters of 550 to 780 mm. This pipe diameter range is a result of the axial stroke of the pneumatic cylinder, or the deflection of the scissor-type mechanism.

The seawater manipulator developed by Ibass can maneuver and inspect pipes with inner diameters of 550 to 780 mm. This pipe diameter range is a result of the axial stroke of the pneumatic cylinder, or the deflection of the scissor-type mechanism.

The scissor drive works with a total of twelve wheels, two each per scissor side and drive motor, which give the vehicle a firm hold even in coated pipes, thanks to their variable contact force. For the drive, a total of six powerful RE motors are used in combination with planetary gearheads – one per wheel pair.

The DC motors are characterized in particular by their efficiency of more than 90%, resulting in low energy consumption and a very high torque, which is an important prerequisite for this application. The motors furthermore are equipped with ironless windings and neodymium magnets, which enable maximum performance packed into a minimum size. The robustness and long service life of the maxon motors were decisive criteria for Ibass.

High motor robustness is vital, as the manipulator has to withstand the on-site conditions – for example, it can handle a pressure of up to 2 bar, this means that it can dive up to 20 m deep. It provides a tractive force of approx. 250 kg (2.5 kN) and the robot can drive a distance of up to 200 m into the pipe. The manipulators are equipped with lights at the front and back. At the front, there is a high-quality camera with pan-tilt head and a 10x zoom; at the rear a single-head camera is mounted. From grinding and testing to inspection and retrieval: The seawater manipulator can be fitted with all Ibass work modules and can overcome up to five pipe bends with ease (see Video). Motors and gearheads by maxon are not only used to drive the seawater manipulator. The work modules are also equipped with RE motors, for example for rotation and axial adjustment of the dye penetration unit. During the dye penetration test, the inner pipe surface is checked for cracks by means of a special method. The in-pipe manipulators are important tools for today’s industries and ensure more safety and reliability, for example in nuclear power plants and offshore wind parks.

About Maxon

In this motion control application, the Swiss specialist for quality drives maxon is a developer and manufacturer of brushed and brushless DC motors, as well as gearheads, encoders, controllers, and entire mechatronic systems. maxon drives are used wherever the requirements are particularly high: in NASA’s Mars rovers, in surgical power tools, in humanoid robots, and in precision industrial applications, for example. To maintain its leadership in this demanding market, the company invests a considerable share of its annual revenue in research and development. Worldwide, maxon has more than 3000 employees at nine production sites and is represented by sales companies in more than 30 countries.

Maxon is a developer and manufacturer of brushed and brushless DC motors, as well as gearheads, encoders, controllers, and entire mechatronic systems. With over 50 years of experience in drive technology, maxon works closely with engineers designing high-tech innovations. maxon drives are used wherever the requirements are particularly high: in NASA’s Mars rovers, in surgical power tools, in humanoid robots, and in precision industrial applications. Worldwide, maxon has more than 2800 employees at nine production sites and is represented by sales companies in more than 30 countries. www.maxongroup.com

Contact maxon for more details https://support.maxongroup.com/hc/en-us/requests/new

Comprehensive documentation and software are included with every delivery, and are also available for you to download from our website at www.maxonmotor.com.

See this and other Motion Control Components from Maxon featured on:

http://MotionControlBlogger.com

http://MotionControlBuyersGuide.com

http://Catalogs-MotionControl.com

September 28th, 2022

September 28th, 2022  Editor-Publisher

Editor-Publisher

Posted in

Posted in